CRT Manufacturing’s innovative STARBAR™ composite rebar not only presents a technological breakthrough but also positions the company as a regional pioneer in reshaping the future of construction. This environmentally conscious alternative signifies a significant step towards a more sustainable industry.

In the construction landscape, where sustainability is an increasingly vital consideration, CRT Manufacturing’s STARBAR™ composite rebar emerges as a game-changer. Its advantages over traditional steel go beyond mere functionality, addressing critical environmental concerns and contributing to a more sustainable future.

Advantages of STARBAR™ over Steel:

- Lower Carbon Footprint

Globally, the construction industry accounts for a substantial 38% of CO2 emissions. STARBAR™ takes a significant stride towards sustainability by supporting a 70% reduction in CO2 emissions compared to traditional steel. This aligns with the industry’s increasing focus on environmental responsibility and sustainable practices.

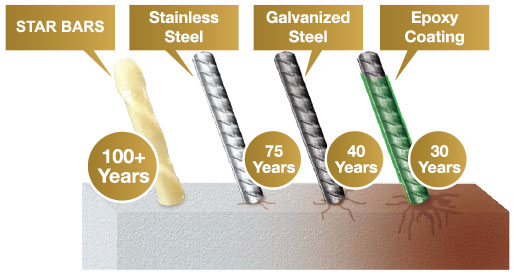

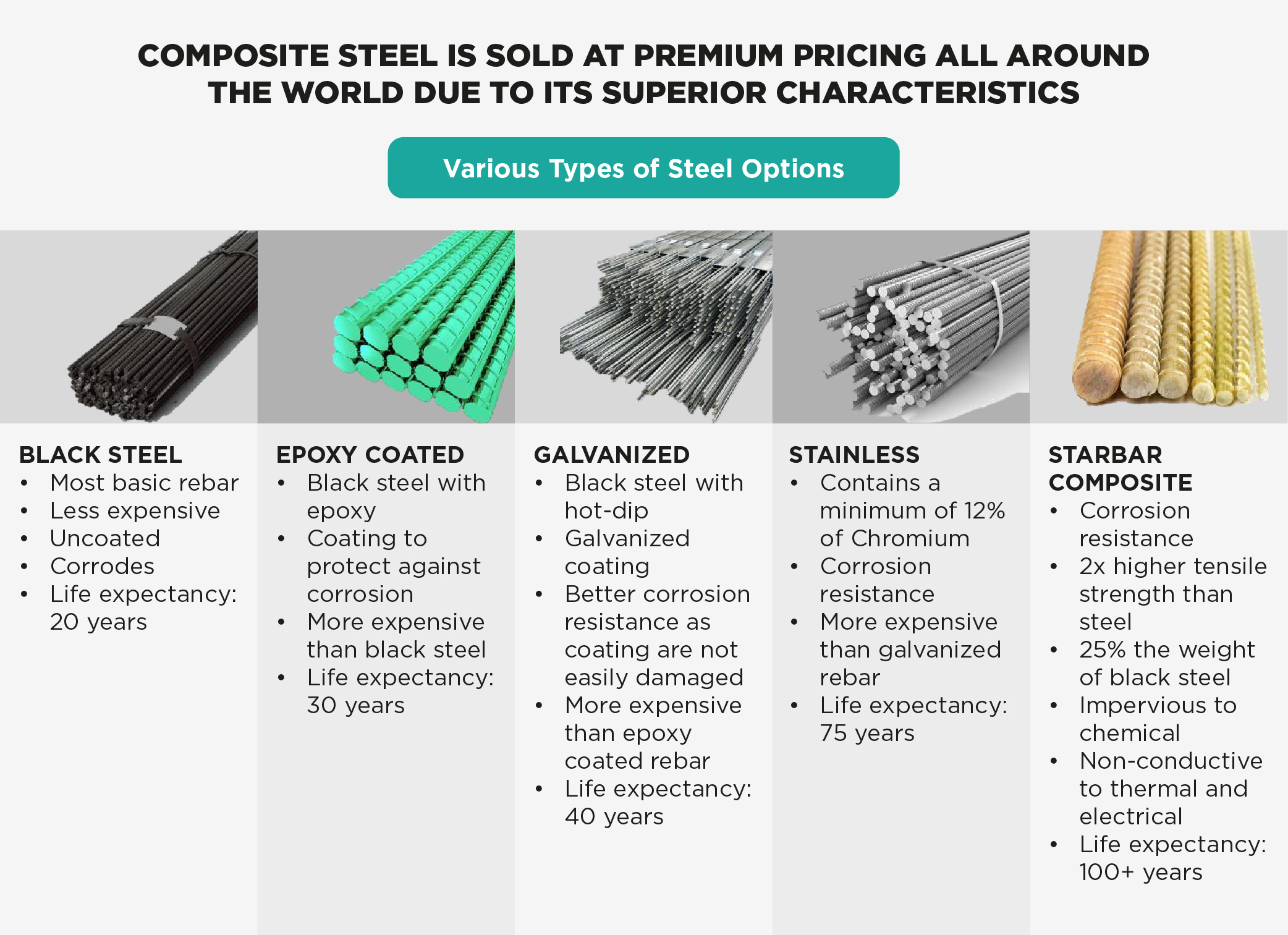

- Reduced Corrosion Concerns

Unlike steel, STARBAR™ is non-metallic, providing inherent resistance to corrosion in environments characterised by high humidity or coastal conditions. This characteristic not only enhances the longevity of structures but also contributes to their overall durability, reducing maintenance needs.

- Recyclability and Reusability

STARBAR™ aligns with the principles of a circular economy by offering recyclability and reusability. This marks a significant stride towards a sustainable construction material, reducing the industry’s reliance on finite resources and minimising waste.

STARBAR™ signifies a step towards a more sustainable, environmentally conscious construction industry, promising a future where traditional steel may no longer be the only option.

Article 2: CRT Manufacturing Unveils Eco-Friendly Alternative to Steel in Building