Malaysian Resources Corp Bhd (MRCB)’s proprietory technology is revolutionising the construction industry to design and deliver bespoke, prefabricated buildings at a fraction of the time it would take using conventional methods.

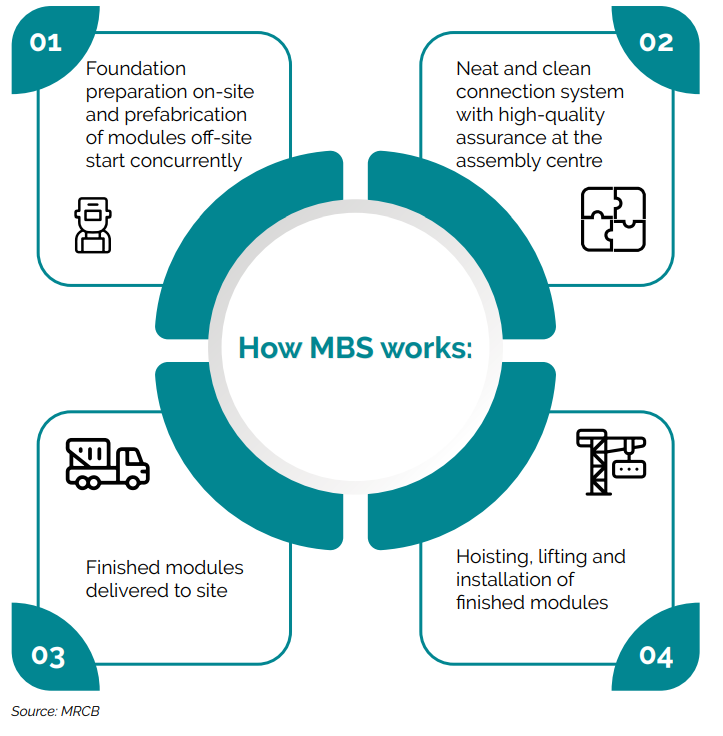

When MRCB unveiled their ground-breaking volumetric building system at International Construction Week (ICW) 2019, it caused a stir amongst the construction community. Known as MRCB Building System (MBS), this advanced system is a combination of Prefabricated Prefinished Volumetric Construction (PPVC) system and a proprietary jointing system called the Candle-Lock Connection System. The latter is a stainless-steel pin and cast iron lateral tie plate used in between each unit to set and lock the units in place both vertically and horizontally.

According to MRCB Executive Vice President Dato’ Sri Ir. Dr. Judin Abdul Karim, the building components will be fabricated completely off-site and delivered to the site where it will be installed using the Candle-Lock Connection System. This proprietary system is a stainless-steel pin and cast iron lateral tie plate used between each module to lock them in place both vertically and horizontally to form a building. “The units can be used for lower, medium and high-end developments like a single storey building, low rise, high rise developments, schools, hospitals, hotels and offices,” he says. “Different modules can be stacked together to form a housing unit and can go up to 40 storeys high. Beyond that, the costs may become too prohibitive.”

MBS offers significant advantages over IBS, including having 95% of the building works done off-site as compared to only about 30% of off-site works done under IBS. This leads to a 30% reduction in project delivery time. In addition to fabricating bare walls, MBS also allows the fabrication of the architectural fittings and interior finishes and takes care of the total customisation of the units. As most of the fabrication work is performed in a controlled environment off-site, this makes it a time- and cost-effective solution that utilises minimal physical labour while improving on-site safety.

In December 2018, MRCB built a 5-storey prototype in Kwasa Sentral using MBS. The project involved developing a flexible system of precast concrete PPVC units. The 2D elements were designed to be assembled into 3D units in a transit factory in Johor and then transported and erected on-site in less than a couple of days. “The whole project took a mere 33 days with just 1.5 days spent on-site,” says Dato’ Sri Ir. Dr. Judin adding that the success of this concept design will enable MBS to be used on projects across Malaysia and regionally through MRCB’s licensees.

“In fact MRCB has licensed the use of MBS in Singapore and Hong Kong and these licensees have won their tenders because of MBS,” he states, adding that modular construction technology has taken off in leaps and bounds in Singapore due to government regulation in promoting the industrialisation of the construction sector. He believes that with a similar impetus from the local government, MBS can transform the landscape of the construction industry. “It is high time that we move away from labour dependency and to spruce up the image of the typical construction site. Technology such as MBS can help us get there.”

Two years ago, MRCB acquired and developed intellectual property rights for a Singapore Building and Construction Authority (BCA)- approved mechanical connection system, now known as MBS. “We acquired the technology and are developing it further, setting a higher standard for our industry,” says Dato’ Sri Ir. Dr. Judin. “Off-site fabrication is becoming an important strategy of the global construction industry. By acquiring the technology behind MBS, we aim to improve quality control, reduce the time to build certain structure types and generate a quicker return on investments.

Listed on Bursa Malaysia’s Main Board since 1971, MRCB is focused on three areas, namely, property development & investment enigineering , construction & environment, and facilities management. The urban property and construction company developed the iconic RM18 billion KL Sentral CBD. It pioneered the Transit-Oriented Development (TOD) in Malaysia, with a glowing track record in highways, rail infrastructure, high voltage power transmission projects and the rehabilitation of rivers and coastal areas. It has a 282-acre urban land bank with an estimated GDV of RM31 billion. Recently, it won the Australasian Reporting Awards (ARA) 2019 Gold Award, which represents the highest standard of reporting in terms of transparency and accountability. MRCB’s largest shareholder is the Employees Provident Fund, making the company especially aware of its duty towards the people of Malaysia.

“As a developer, it is a painful thing to receive customer complaints due to quality issues. To reduce these types of complaints, MBS is the only way to go forward. Why leave things to chance when you can utilise a technology that offers better quality control leading to satisfied customers?” he emphasises. Since developers need to pay the penalty if they do not deliver vacant possession within the promised time, they are motivated to complete their projects on time and within budget. With shorter build times and increased site productivity, MBS helps MRCB to keep to the project plan, and even resulting in an early completion, which allows for a quicker realisation of the building’s earning potential.

Modules are the vital components in modern-day construction, and they are built to last upwards of 30 to 40 years. “There is, of course, a steep learning curve for contractors who have done things the traditional way of building everything on site. It requires a new business model and skill set, but the rewards alone are worth the investment.” While IBS is an effective technology, Dato’ Sri Ir. Dr. Judin states that there will be a need for more advanced systems like MBS to meet the demands of the buyers of tomorrow. “The MBS system offers the latest features of automation and is made to complete construction projects with shorter build times while ensuring better quality control and efficiency, and reduced dependence on manpower. As such, MBS is a major breakthrough and will revolutionise the landscape of the construction industry in Malaysia,” he concludes.